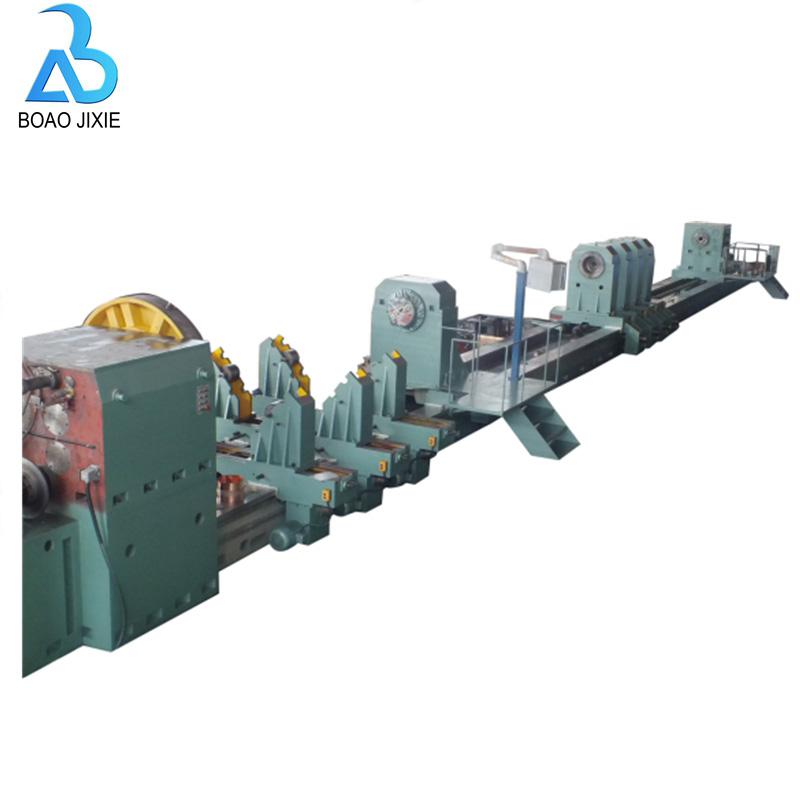

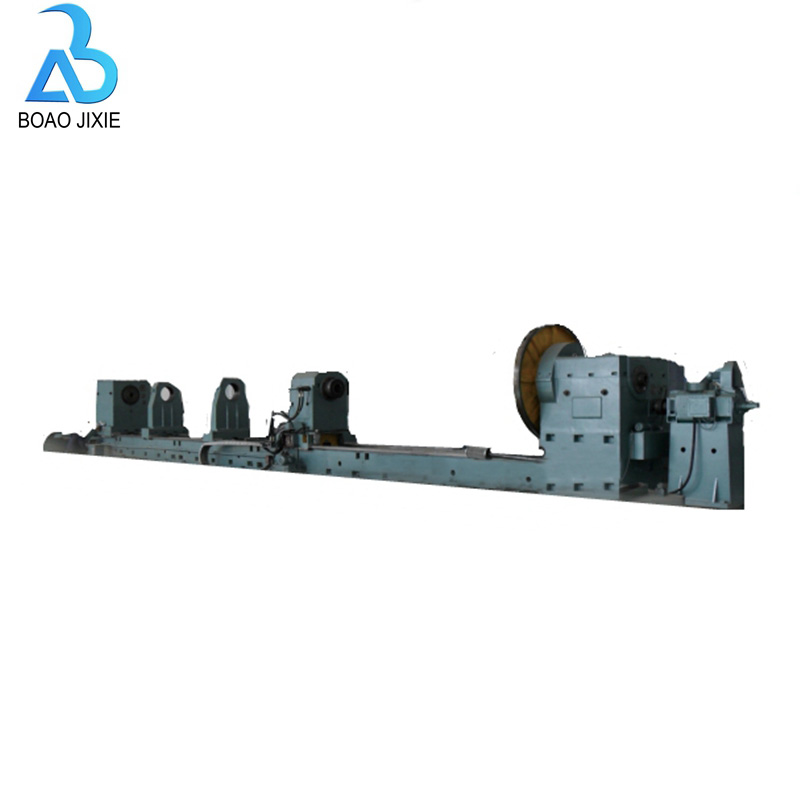

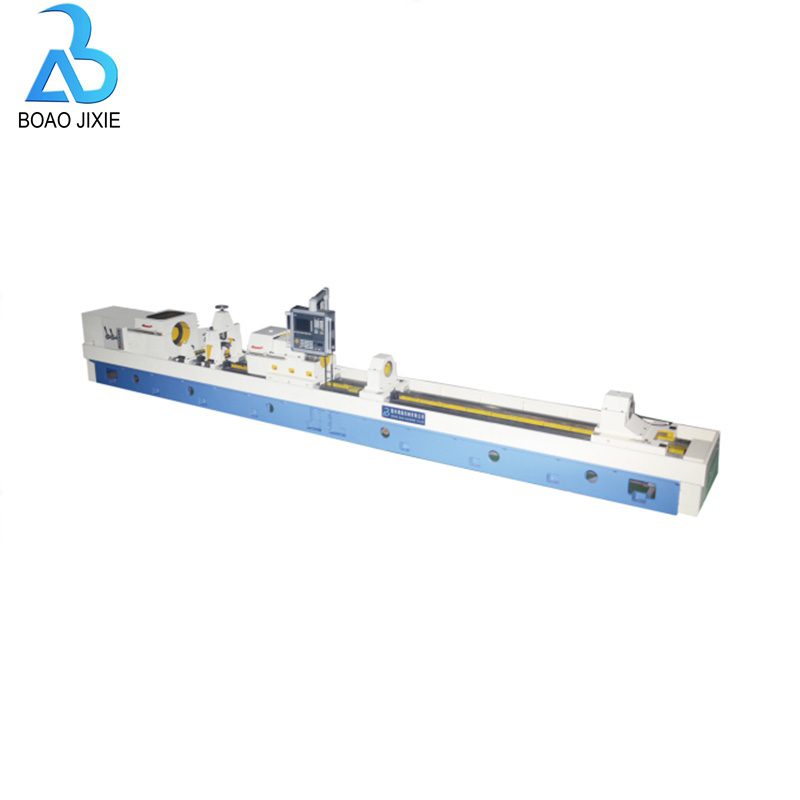

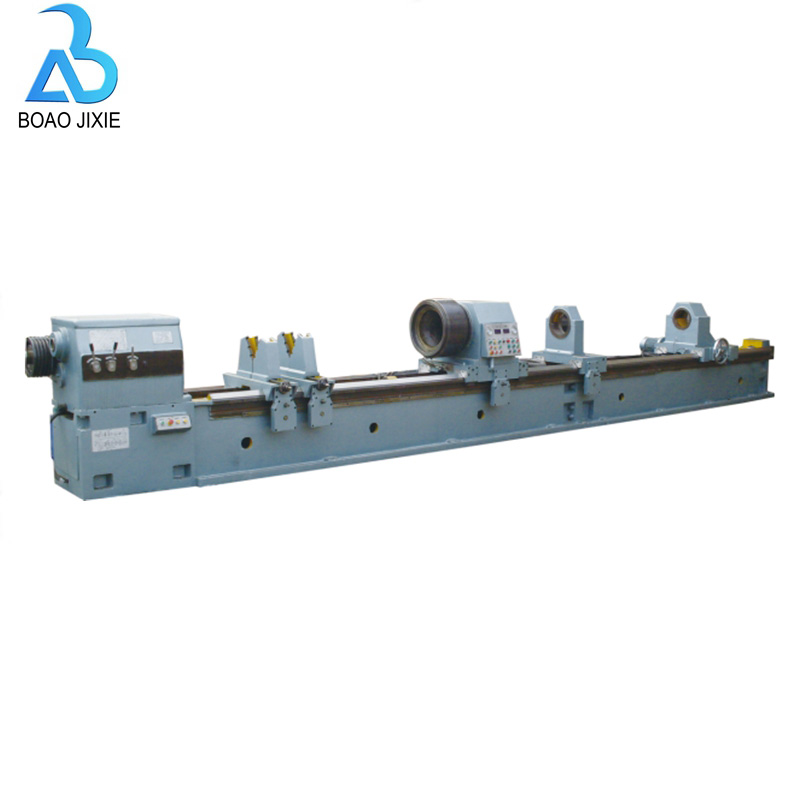

CNC Umsebenzi onzima woMgongxo oNzulu woMngxuma & oomatshini abaBorayo

Ingcaciso yeMveliso

Umatshini we-T2150 ngowokwenza umsebenzi we-cylindrical workpiece.Isixhobo sigcinwa sijikeleza kwaye sondla, lo matshini unokwenza inkqubo yokubhoboza, ukubhoboza, ukwandisa kunye nokutshisa i-roller, njl njl. Umatshini uhlanganiswe nenkqubo ye-CNC.Ngaphandle komatshini wokutyhutyha umngxuma, inokuphinda iqhube umngxuma wokunyathela kunye nomngxuma oyimfama.I-spindle ye-headstock iqhutywa ngamandla amakhulu e-DC motor, isebenzisa utshintsho lwe-multi-gear speed kunye nommiselo wesantya esingenasinyathelo.Inkqubo yamkela imowudi ye-workpiece ejikelezayo kunye nokutya kwezixhobo, i-coolant inikezelwa yi-oyile feeder okanye ekupheleni kwebar ekruqulayo, i-chip ityhilwa ngaphandle koxinzelelo lokupholisa.

Inxalenye ye-headstock ixhotyiswe nge-chuck yemihlathi emithathu okanye emine-yemihlathi emine, i-oyile yokutya ibamba i-workpiece nge-servo motor.I-oyile yesondlo inokushukunyiswa kwaye ibekwe ecaleni komzimba webhedi, kunye nokugcina amandla okubamba rhoqo kwindawo yokusebenza.Inkqubo ye-hydraulic inolawulo olulungileyo xa i-clamping kwaye ilungisa i-workpiece, enozinzo oluphezulu kunye nokuchaneka okulungileyo.I-oyile feeder ithatha isiseko se-axis isakhiwo esiphucula umthamo womthwalo kunye nokuchaneka kokujikeleza.

Umzimba webhedi wenziwe ngamandla aphezulu entsimbi, eqinisekisa ukuba umatshini unobungqongqo okwaneleyo.Umkhondo wesikhokelo uphathwa ngobuchwephesha obunzima kwaye unokumelana nokunxiba okugqwesileyo kunye nobuchule obuphezulu bokugcina obuchanekileyo.Zonke iiparamitha zokusebenza ziboniswa ngumboniso wemitha (Iphaneli yeCNC ibekwe kwicala eliphakathi lomatshini), i-workpiece clamping kunye nokusebenza kukhuselekile kakhulu, ngokukhawuleza kwaye kuzinzile.Lo matshini usetyenziswa ngokubanzi kwimveliso ye-cylinder ekhethekileyo, i-cylinder yamalahle, oomatshini be-hydraulic, ityhubhu ye-boiler yoxinzelelo oluphezulu, i-petroleum, imikhosi, i-electrics kunye ne-airspace industry.

Iinkcukacha

| NO | Izinto | Iiparamitha | |

| 1 | Iimodeli | TK2250 | TK2150 |

| 2 | Uluhlu lwedamitha yokwemba | / | Φ40-Φ150mm |

| 3 | Kukhale idiameter edikayo | Φ120-Φ500mm | Φ120-Φ500mm |

| 4 | Max.ubunzulu bodikadika | 1000-18000mm | 1000-18000mm |

| 5 | Uluhlu lwedamitha yokudibanisa i-workpiece | Φ150-Φ650mm | Φ150-Φ650mm |

| 6 | Machine spindle ukuphakama iziko | 625mm | 625mm |

| 7 | Uluhlu lwesantya sokujikeleza kwe-headstock spindle | 1-225r / min | 1-225r / min |

| 8 | Idayamitha yomngxuma wokusonta | Φ130mm | Φ130mm |

| 9 | Idayamitha yomngxunya we taper ngaphambili | Metric 140# | Metric 140# |

| 10 | Headstock motor amandla | 45KW , DC motor | 45KW , DC motor |

| 11 | Drill ibhokisi motor amandla | / | 22KW |

| 12 | Driba ibhokisi umngxuma spindle ububanzi | / | Φ75mm |

| 13 | Umngxuma we taper wangaphambili webhokisi yokubhora | / | Φ85mm 1:20 |

| 14 | Isantya sebhokisi yeDrill yakhala | / | 60-1000 r / min |

| 15 | Uluhlu lwesantya sokutya | 5-3000mm/min(inyathelo) | 5-3000mm/min(inyathelo) |

| 16 | Ukutya inqwelo yesantya ekhawulezayo | 3m/mz | 3m/mz |

| 17 | Ukutya amandla emoto | 7.5KW | 7.5KW |

| 18 | Ukutya kwikhareji amandla emoto ngokukhawuleza | 36N.M | 36N.M |

| 19 | Injini yepompo yeHydraulic | N=1.5KW | N=1.5KW |

| 20 | Uxinzelelo lomsebenzi olinganisiweyo we-hydraulic system | 6.3Mpa | 6.3Mpa |

| 21 | Ukupholisa injini yempompo | N=7.5KW(2 amaqela), 5.5KW(1iqela) | N=7.5KW(2 amaqela), 5.5KW(1iqela) |

| 22 | Uxinzelelo lomsebenzi olinganisiweyo wenkqubo yokupholisa | 2.5Mpa | 2.5Mpa |

| 23 | Ukuhamba kwenkqubo yokupholisa | 300, 600, 900L/min | 300, 600, 900L/min |

| 24 | Inkqubo yokulawula ye-CNC | Siemens 808/ KND | Siemens 808/ KND |

Qaphela: inkqubo yolawulo lwamanani ayinyanzelekanga